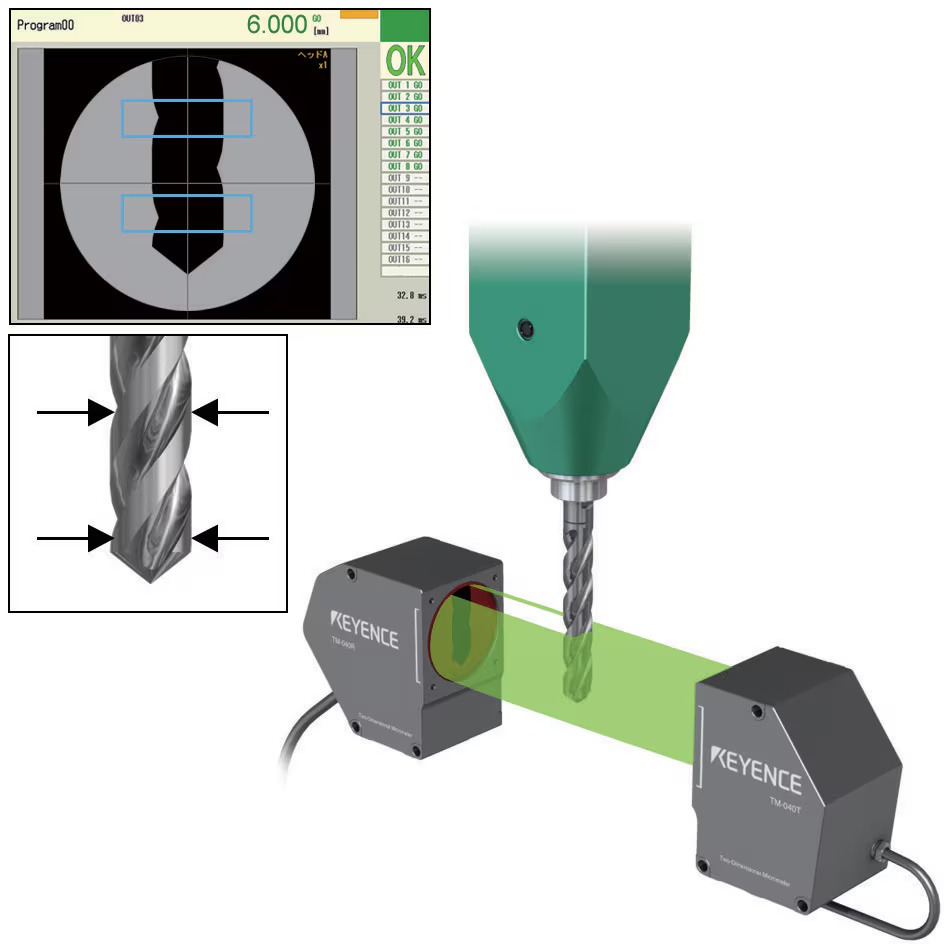

Measuring the Outside Diameter After Sharpening the Tool

Applications for Aut...Description

As the accuracy required for products increases, so does the accuracy required for tools. With the high-speed projection type 2D measuring sensor, anyone can easily measure the outer diameter of the tool after resharpening.

Actions

Share

Related Products

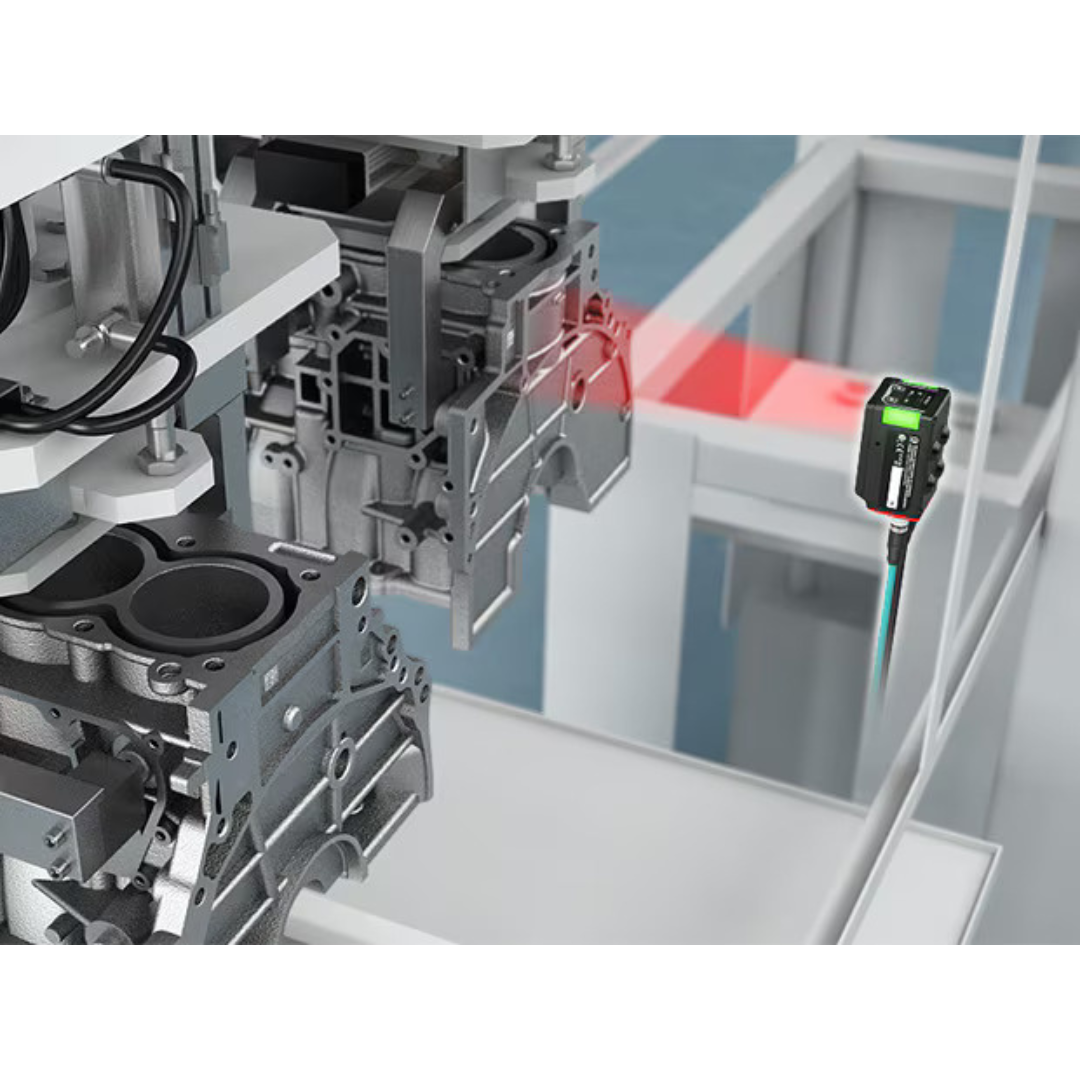

Checking Code Quality During Delivery to Improve the Quality of Goods Sent

<p>Failure to verify code compliance on delivery with ISO standards means that failure to read could result in the product being shipped without leaving any records. Use the 1D/2D Code Reader's built-in Code Verification Function to check and record code compatibility with ISO/IEC TR29158 standards.</p><p style="text-align: center;"><strong>Conventional Products</strong></p><p><img src="https://www.keyence.co.id/img/application/95059.png"></p><p>Unable to check conformance with ISO standards</p><p style="text-align: center;"><strong>1D/2D Code Reader Unitek</strong></p><p><img src="https://www.keyence.co.id/img/application/95060.png"></p><p>Assess print quality in accordance with ISO/IEC TR29158!</p>

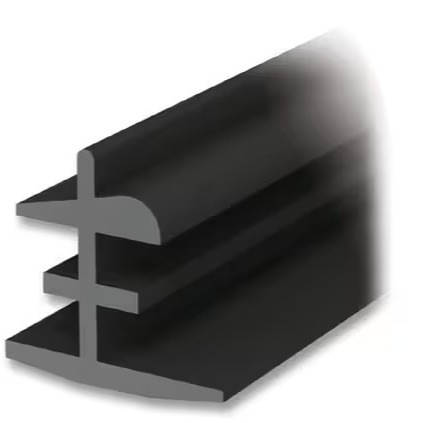

Measurement on Weather Strip

<p>Profile tolerance measurements can be done easily by comparing them with CAD drawings or master samples.</p><p><img src="https://www.keyence.co.id/img/application/92801.jpg"></p>

Measurements on Oil Seals, O-Rings and Mechanical Seals

<p>In addition to the inner and outer diameters, the minimum and maximum diameters can also be measured easily. Weld residue can also be recognized and measured automatically.</p><p><img src="https://www.keyence.co.id/img/application/90839.jpg"></p>